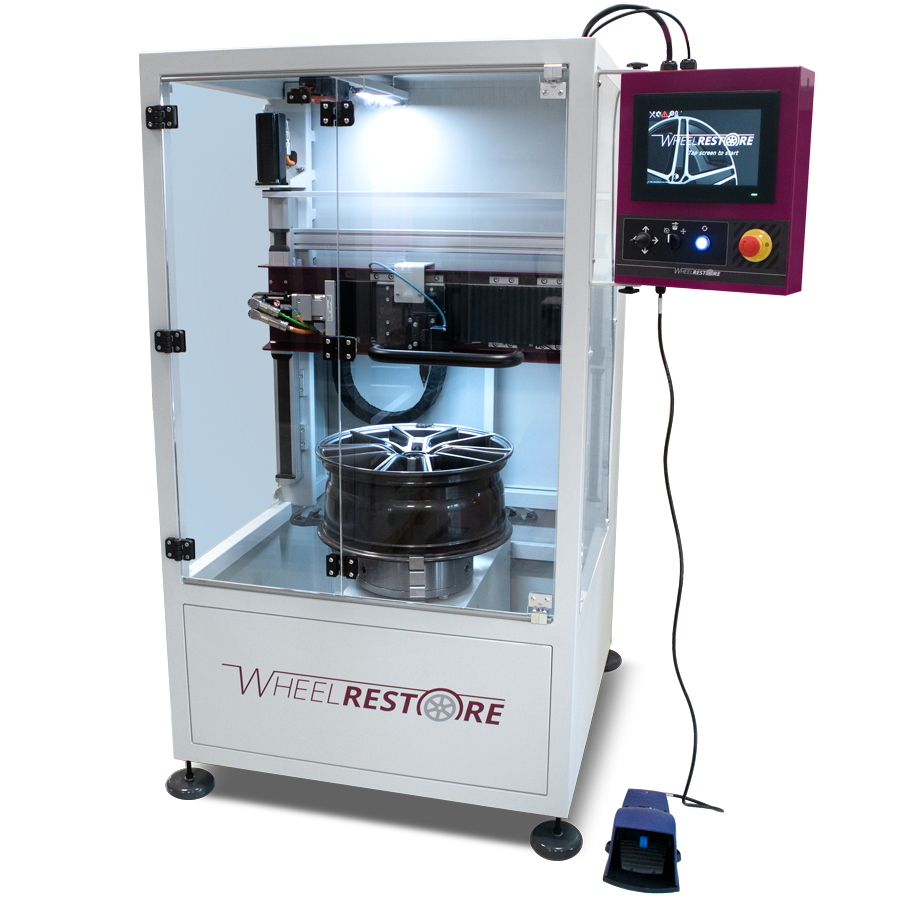

THE WR-DCM3 – DIAMOND CUT MACHINE

Smart tailor-made piece of software

Premium quality components

Well designed and modern appeareance

Robust chassis & light weight – weighs only 390 Kgs

The latest technology in alloy wheel diamond cut machinery

The Wheel restore products has been designed from the ground up to be best to none in the refinishing process for Alloy wheel refurbishment

Key Points

- Ergonomically designed for loading wheels easily.

- Average speed probing 1 minute.

- Flexibility to cut wheels with or without the tyre on.

- The only machine capable to cut a Max wheel diameter of 30”.

- Not a mechanical touch probing system. Ours uses Laser.

- Automatic wheel profile software optimization.

- Straight from wheel profile reading to wheel cutting.

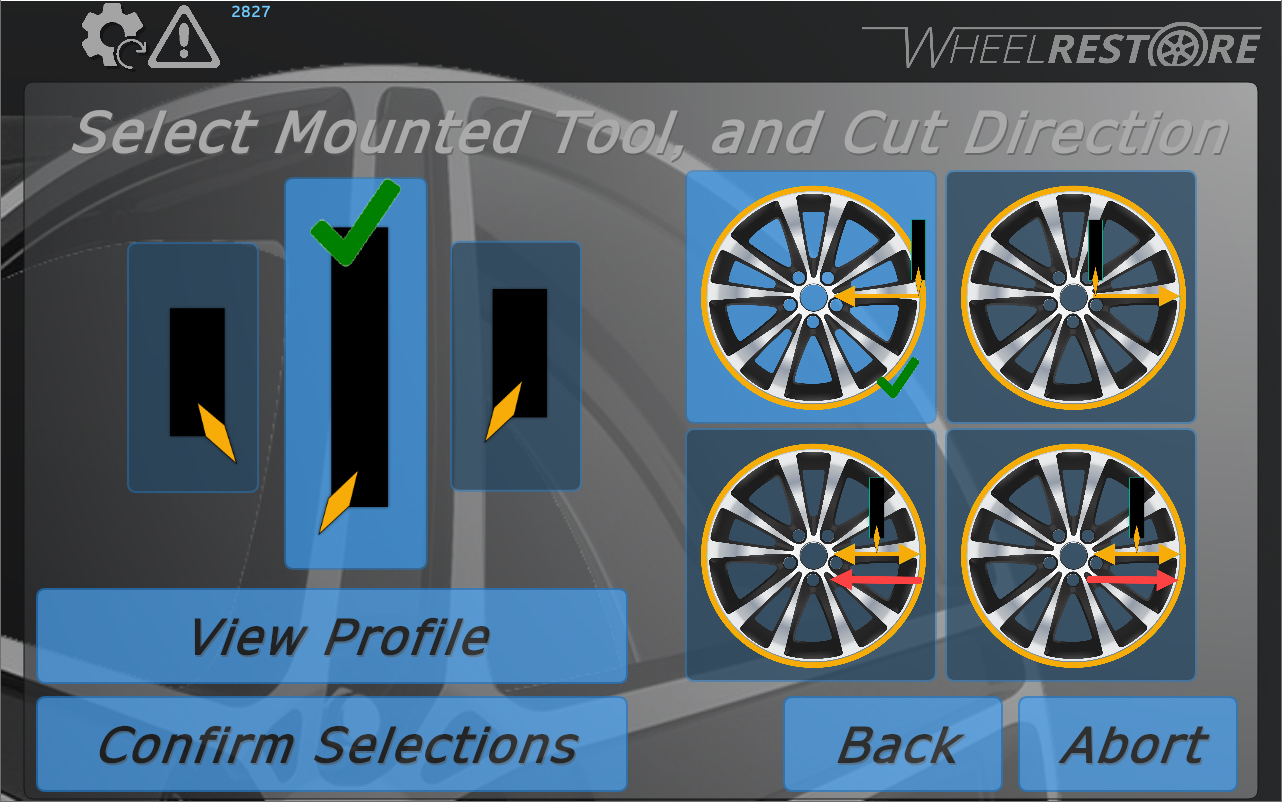

- Flexible initial cutting process set up to avoid wheel over-cutting.

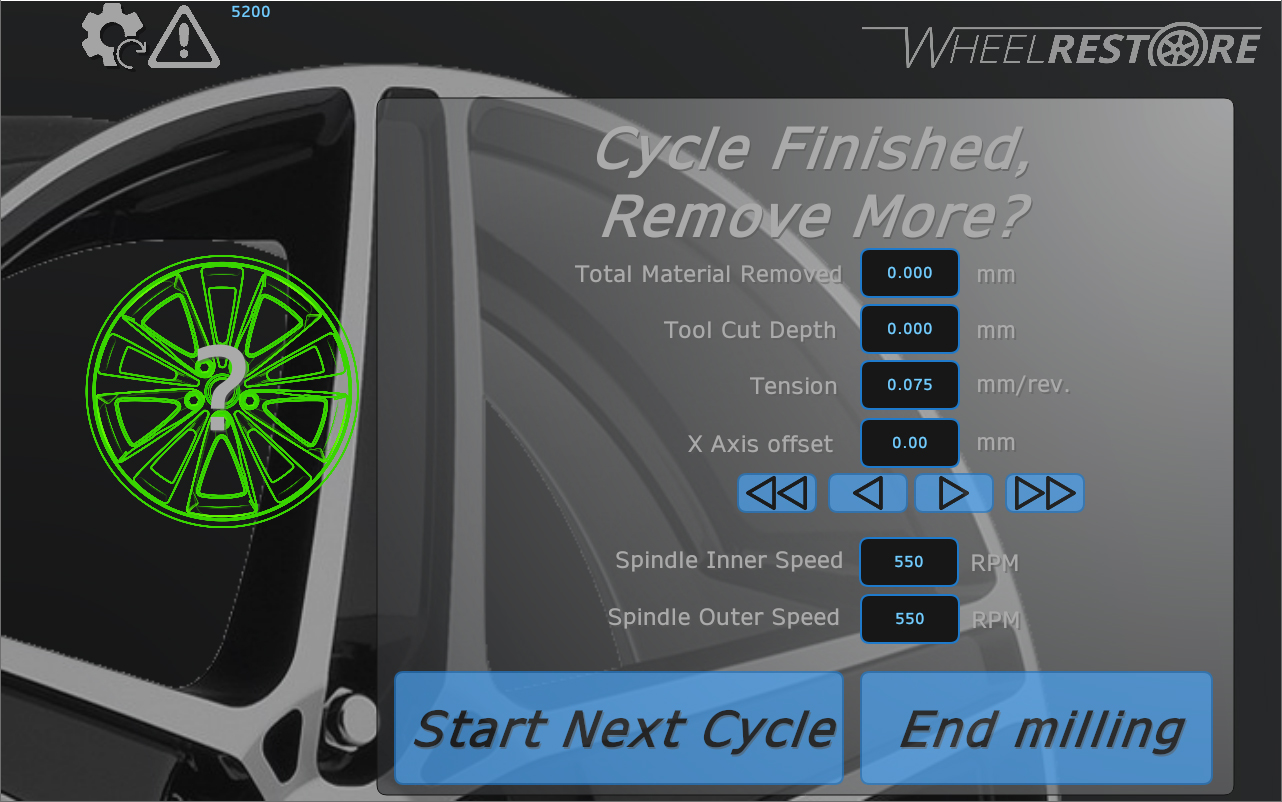

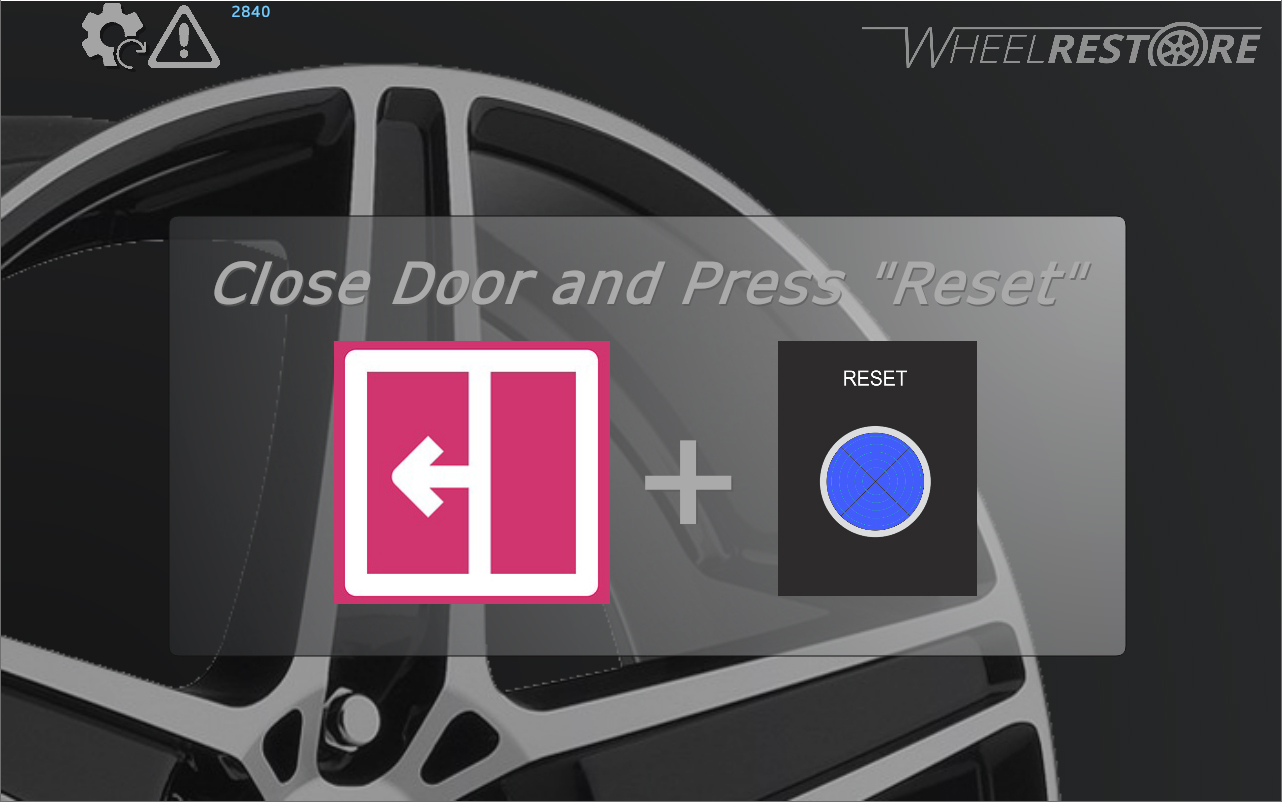

- Intuitive step-by-step operator user software.

- Easy use, only 2 hours training.

- Measure accuracy <0.015.

- 100% electric and electronic components by German Schneider Electrics.

- Components available at any local Schneider distributor.

- Normal Wheel process from probing to finish 10 – 15 minutes.

Intuitive Software

At the core of the Alloy Wheel Repair Machine is a tailor-made piece of software designed and engineered in Denmark. The software clearly visualizes each step of the repair procedure on the touch screen interface.

Safety

Safety first! The machine is designed to fulfill all the latest international Alloy Wheel Diamond Cut Machine regulations.

» Meets the ISO 23.125 directive (Machine tools -Safety -Turning Machines)

» CE confirmative declaration

» Includes full risk assessments guides

» Built according to international electric guidelines – supplied with mandatory certified operator training

» Meets the ISO 23.125 directive (Machine tools -Safety -Turning Machines)

» CE confirmative declaration

» Includes full risk assessments guides

» Built according to international electric guidelines – supplied with mandatory certified operator training